Mar 01 , 2020

Stamping mold is the process to exert pressure on the blank so that the blank will undergo steel transformation or separation to produce workpieces with fixed sizes, shapes and properties, stamping process can be divided into separating and forming.

Common stamping process

1. Separating Process

Process ...read more

Feb 29 , 2020

Below specification defines E-mold acceptance criteria of cosmetic inspection.

Classification on product surfaces.

Class 1 Surface: Visible "ofter" by user.

Class 2 Surface: Visible occasionlly or likely to be seen by user.

Class 3 Surface: Normally not visible or only visible during installation.

1. Acceptance...read more

Feb 28 , 2020

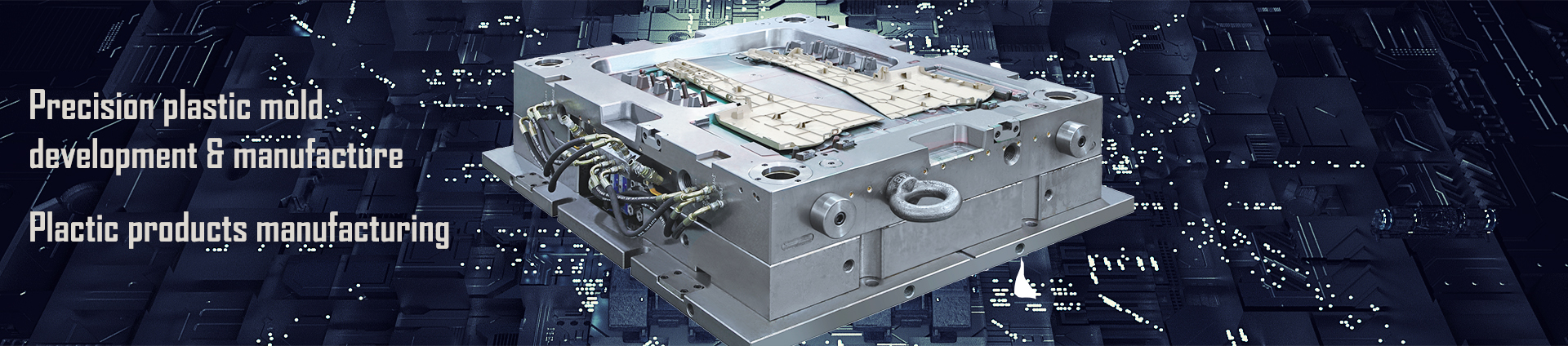

Injection molding is principally used for the production of thermoplastic parts, although some progress has been made in developing a method for injection molding some thermosetting materials.

The problem of injecting a melted plastic into a mold cavity from a reservoir of melted material has been extremely difficult to solve for thermosetting plastics...read more

Feb 23 , 2020

A complete stamping press tool for cutting two holes in work material at one stroke of the press is shown in Figure 1. Its type is a single-station piercing stamping mold.

Any complete stamping press tool, consisting of a pair(or a combination of pairs) of mating members for producing stamped parts, including all supporting and actuating...read more

Feb 22 , 2020

The parts of an injection mold are divided into the following categories based on their different functions.

a) Mold closing state b) Mold opening state

1-Moving half of a mold; 2-Fixed half of a mold; 3-Cooling channel; 4-Clamping plate of the fixed half; 5-Locating ring; 6-Sprue bush; 7- Punch; 8-Guide pillar; 9-Guide...read more

Feb 06 , 2020

Alloy steels are basically carbon steels with additional elements added to alter the characteris-tics and bring about a predictable change in the mechanical properties of the alloyed metal. Alloy steels are not normally used for most tools due to their increased cost, but some have been found favor for special applications. The alloying elements used most...read more

Aug 09 , 2019

General Tolerances @ E-Mold (apply unless specified otherwise)

CNC (Metals): DIN ISO 2768 fine,

CNC (Plastics): DIN ISO 2768 medium

GENERAL TOLERANCES FOR LINEAR AND ANGULAR DIMENSIONS (DIN ISO 2768 T1)

LINEAR DIMENSIONS:

Permissible deviations in mm for ranges in nominal...read more

Jul 05 , 2019

Anodizing is used to increase surface hardness, wear resistance and dielectric strength.

Anodizing can also provide a good base for painting or colouring, creating an extremely stable but porous oxide layer on the surface of aluminum.

Type ...read more

May 25 , 2019

The top 7 forms of CNC machining drive the development of method of metal components and parts during the manufacturing process in the industry.

With the rise in technology, machining techniques have evolved over time. While many conventional and modern techniques are in the effective uses, CNC still remains as one of the most effective and...read more

May 23 , 2019

The plastic injection molding cycle consists of four phases:

1. Clamping is the closing of the mold.

2. Injection is the filling of the mold.

3. Cooling is the hardening of the plastic within the mold.

4. Ejection is the removal of the plastic part from the mold.

Clamping

During the clamping portion of the injection...read more