Design of piercing stamping mold

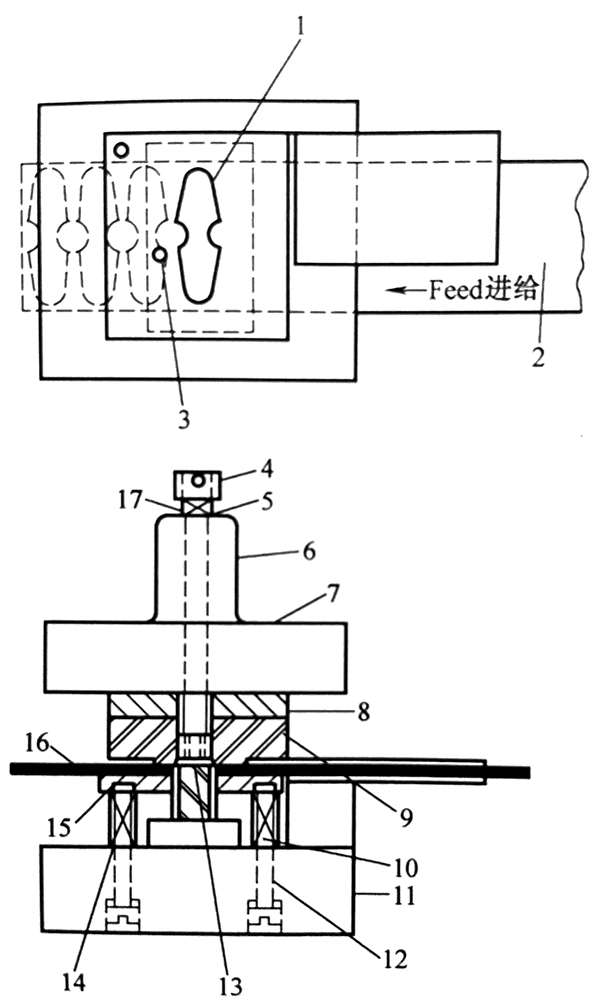

A complete stamping press tool for cutting two holes in work material at one stroke of the press is shown in Figure 1. Its type is a single-station piercing stamping mold.

Any complete stamping press tool, consisting of a pair(or a combination of pairs) of mating members for producing stamped parts, including all supporting and actuating elements of the tool, is a mold. Stamping terminology commonly defines the famale part of any complete press tool as a mold.

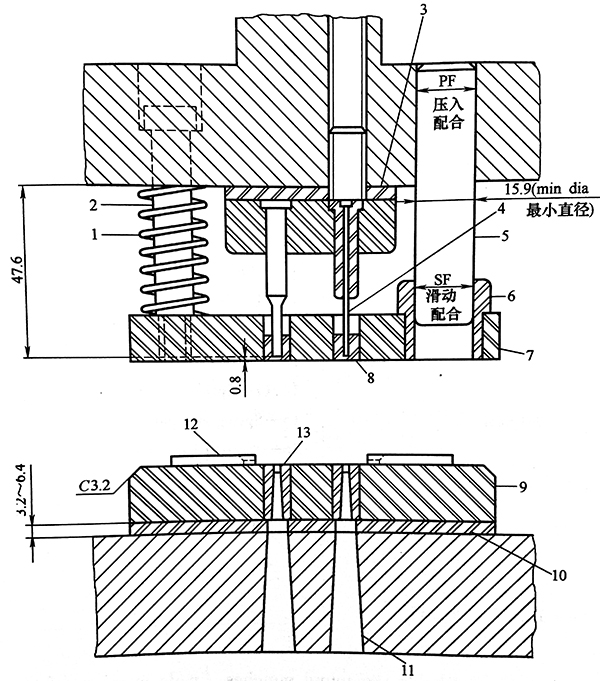

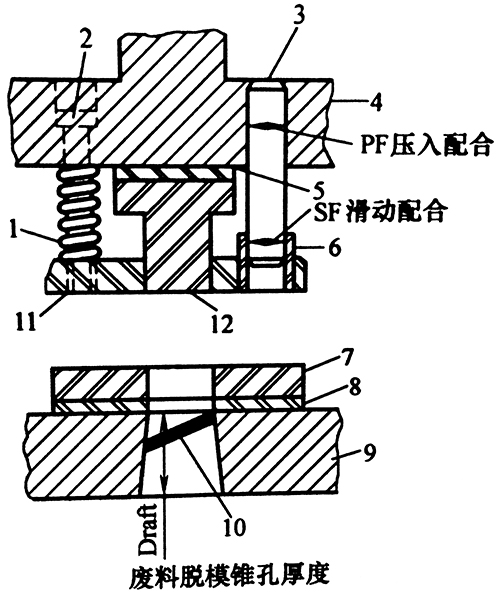

The guide pins, or pillars, are mounted in the mold holder. The punch holder contains bushings which slide on the guide pins. The assembly of the mold holder and punch holder with guide pins and bushing is a mold set. Mold sets in many sizes and designs are commercially available. The guide pins shown in Figure 2 & 3 guide the stripper in its vertical travel. For clarity, the guide pins are not shown in Figure 3.

Figure 1: Typical single-station stamping mold for piercing holes

1-Comp spring; 2-Stripper bolt; 3,10-Backing plate; 4-Quill puch; 5-Guide pin(when bushing are used in stripper); 6-Guide bushing; 7-Stripper; 8-Bushing in stripper for small puches and close limit punches; 9-Die Block(soft); 11-Taper reamer; 12-Nests hdn and grd; 13-Die bushing

Figure 2: A simple blanking stamping mold

1-Stripper spring; 2-Stripper bolt; 3-Guide pin; 4-Punch holder;5,8-Support plate; 6-Guide bush; 7-mold;8-Mold holder;10-Blank; 11-Stripper; 12-Stright punch

1-Blank contour; 2-Strip; 3-Stop pin; 4-Stop collar; 5-Knockout rod; 6-Shank; 7-Punch holder;8-Support plate;9-Mold; 10-Punch; 11-Mold holder; 12-Stripper bolt; 13-Blank; 14,17-Spring; 15-Spring stripper; 16-Scrap strip

A punch plate mounted to the punch holder holds two round punches (male members of the mold) which are guide by bushing inserted in the stripper. A sleeve, or quill, encloses one punch to prevent its buckling under pressure from the slide block of the press. After penetration of the work material, the two punches enter the mold bushings for a slight distance.

The female member, or mold, consists of two die bushings inserted in the mold block. Since this press tool punches holes to the diameters required, the diemeters of the die bushings are larger than those of the punches by the amount of clearance.

Since the work material stock or workpiece can cling to a punch on the upstroke, it may be necessary to strip the material from the punch. Spring-loaded strippers hold the work material against the mold block until the punches are withdraw from the punched holes. A workpiece to be pierced is commonly held and located in a nest (Figure 1) composed of flat plates shaped to encircle the outside part contours. Stock is positioned in dies by pins, blocks, or other types of stops for locating before the downstroke of the slide block.