Apr 17 , 2024

Steel and Cast iron are the most common ferrous metals in general use.

1. Steel

There are two general kinds of steel, carbon steel and alloy steel.

1.1 Carbon Steel

Carbon Steel are classified according to the percentage of carbon they contain.

a. Low carbon...read more

Oct 11 , 2023

Additives are usually added into polymers to modify and improve certain characteristics, such as stiffness, strength, color, weatherability, flammability, arc resistance for electrical applications, and ease of subsequent processing. These additives are described below:

1. Fillers

Fillers are particles added to plastics to...read more

Sep 23 , 2023

The injection parts stick to the mold, making it rather difficult for ejection.

Below are some reasons that caused the issue:

1. Too much injection materials.

2. Overhigh injection pressure, overlarge dwell pressure and overlong dwell time.

3. Overhigh melt temperature.

4. Overhigh mold temperature.

5. Incorrect design...read more

Aug 28 , 2023

Injection molds have a limited service life, appropriate measure can greatly extend this. Here share the methods which E-Mold used to cleaning, maintenance and storage of our customer's injection molds.

1. Cleaning and Maintenance of Heating and Cooling Channel

Heating and cooling channels must be cleaned thoroughly to...read more

Jun 06 , 2023

The design of the component can have an enormous effect on the cost of manufacturing.

1. Material Types

The most easily machined types of metals include aluminum, brass, and softer metals. As materials get harder, denser and stronger, such as steel, stainless steel, and exotic alloys, they become much harder to machine...read more

Nov 14 , 2022

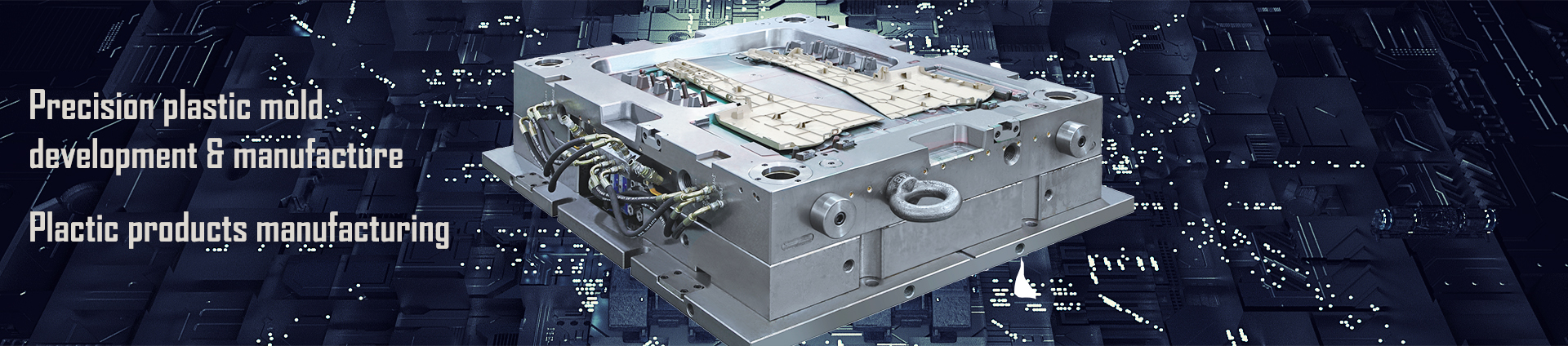

Basic Injection Mold Types

The most common injection mold types which used in E-Mold: two-plate mold; three-plate mold; hot-runner mold.

1. Two-Plate Mold

A two-plate mold consists of two plates with the cavity and cores mounted in either plate. The plates are fastened to the press platens. The moving half of the...read more

Jun 27 , 2022

Hard-coat with Teflon (MIL-A-63576A)

The main purposes of hard anodizing is to make the aluminum more resistant to corrosion. The PTFE(Polytetrafluoroethylene) coating is typically far thicker and harder than normal anodizing.

Types of PTEF coating: The anodic coating to be impregnated or coated shall meet the...read more

Apr 08 , 2020

— Special Processing of Precision Mold & Rapid tooling in E-Mold Rapid Manufacturing

1. EDM

Electrical discharge machining process is: between the tool and workpiece continually occur pulsed spark discharges producing local, transient high temperature, which keeps the metal melting, gasifying and removing. Sparks...read more

Mar 19 , 2020

There is a noticeable trend towards the use of aluminium alloys for medium- to high- volume production in recently years.

The principal advantages of this material are:

1. It costs less than steel.

2. It has good machineabilty: it machines up to 5–10 times faster than steel.

3. Distortion from machining is minimal compared to...read more