Surface textures and finishes

The Average Surface roughness (Ra) is specified in microns (Ra=Arithmetic mean)

The level of surface roughness should be confirmed by customer, sometimes it is better to use a reference sample.

| SPI-Surface Finish | Method of achieving surface finish | µm(Min>Max) | µ inch(Min>Max) | Description |

| A1 (optical quality finish) | 3 micron diamond paste | 0 > 0.025 | 0 > 1 | For mirror or optical finishes. Most time consuming. Steel grade important to results. |

| A2 (mirror finish) | 6 micron diamond paste | 0.025 > 0.05 | 1 > 2 | |

| A3 (High polish) | 15 micron diamond paste | 0.05 > 0.075 | 2 > 3 | |

| B1 | 600 grit fine paper | 0.05 > 0.075 | 2 > 3 | Removes all tool machining marks. Provides good mold release. Light reflecting finish on molded part, some sheen. |

| B2 | 400 grit fine paper | 0.1 > 0.125 | 4 > 5 | |

| B3 | 320 grit fine paper | 0.225 > 0.25 | 9 > 10 | |

| C1 | 600 grinding wheel of stone | 0.25 > 0.3 | 10 > 12 | Removes all tool and machining marks. Provides good mold release. Mute finish on molded part, no sheen. |

| C2 | 400 grinding wheel of stone | 0.625 > 0.7 | 25 > 28 | |

| C3 | 320 grinding wheel of stone | 0.95 > 1.05 | 38 > 42 | |

| D1 (Satin finish) | #11 glass bead dry blast | 0.25 > 0.3 | 10 > 12 | For decorative finishes. Often used for die cast and thermoset cooling. Helps hide shrink marks and other imperfections. Dull, non reflecting finish on molded or cast part. |

| D2 (Dull finish) | 240 A1203 grit dry blast | 0.65 > 0.8 | 26 > 32 | |

| D3 (Dull finish) | #24 A1203 dry blast | 4.75 > 5.75 | 190 > 230 |

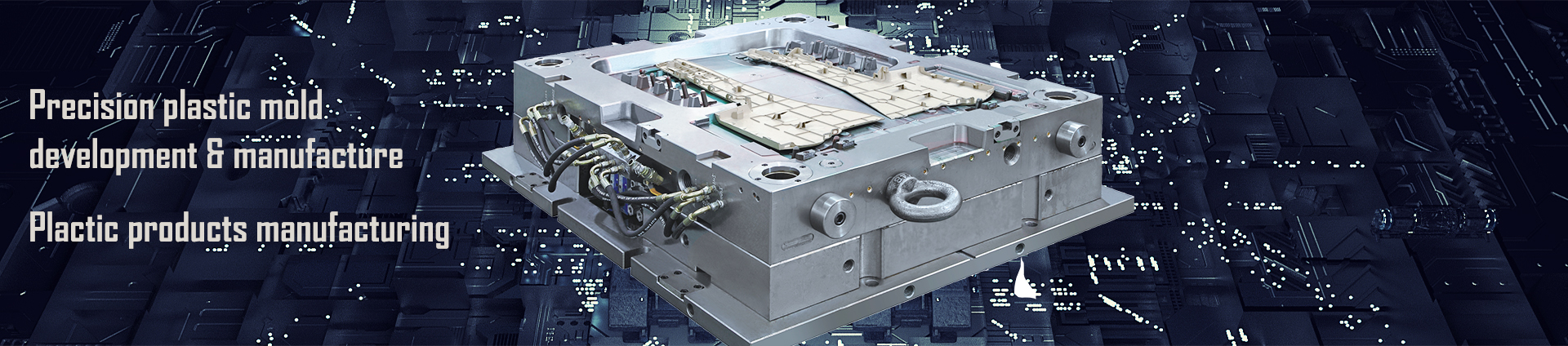

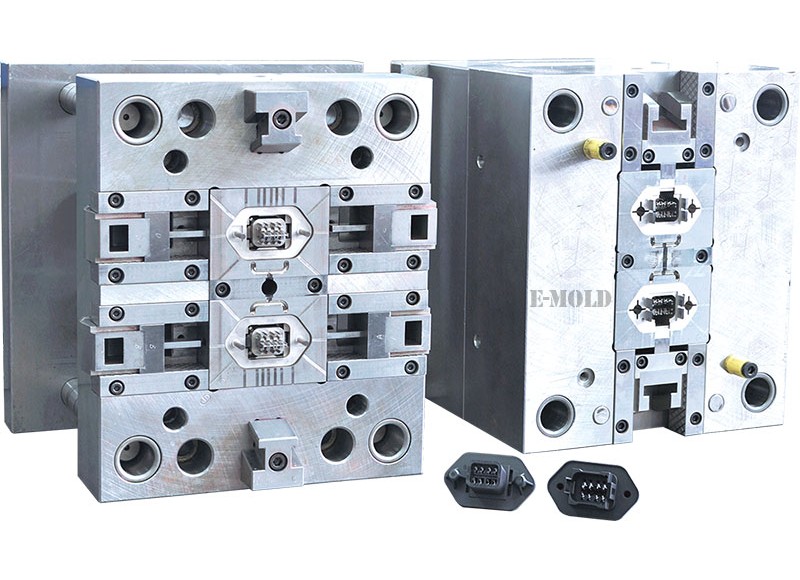

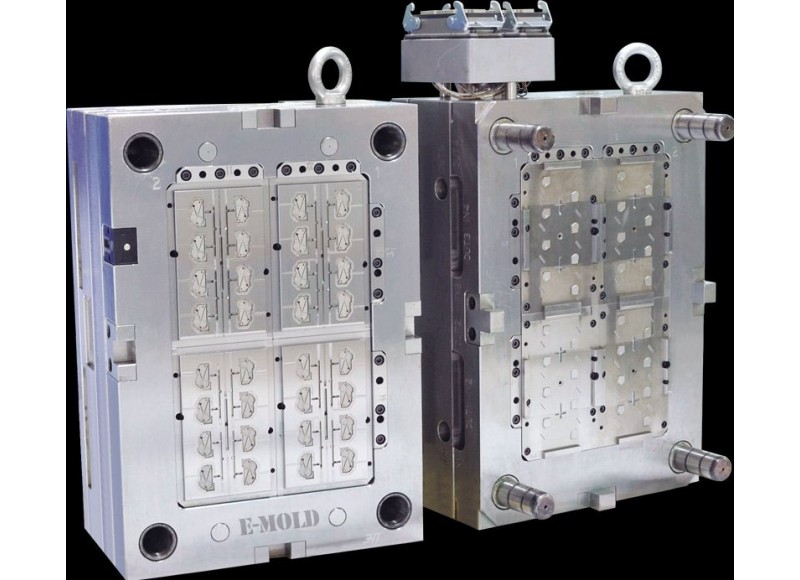

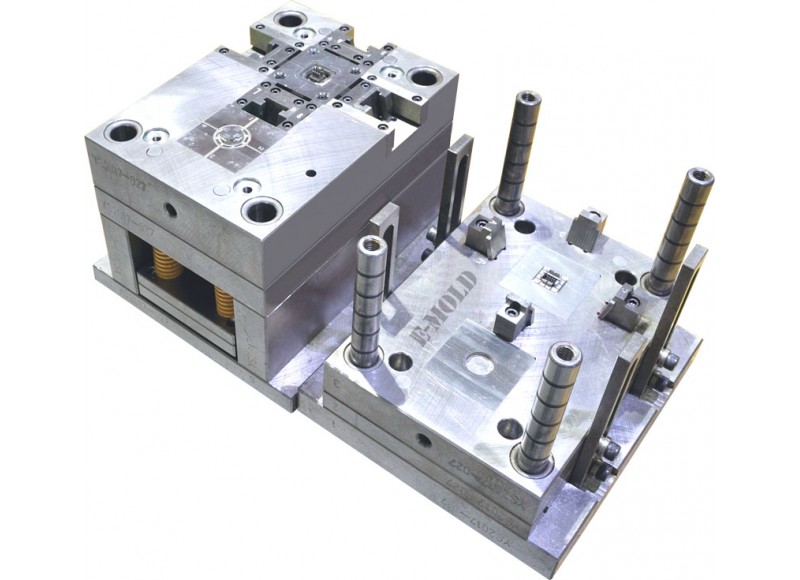

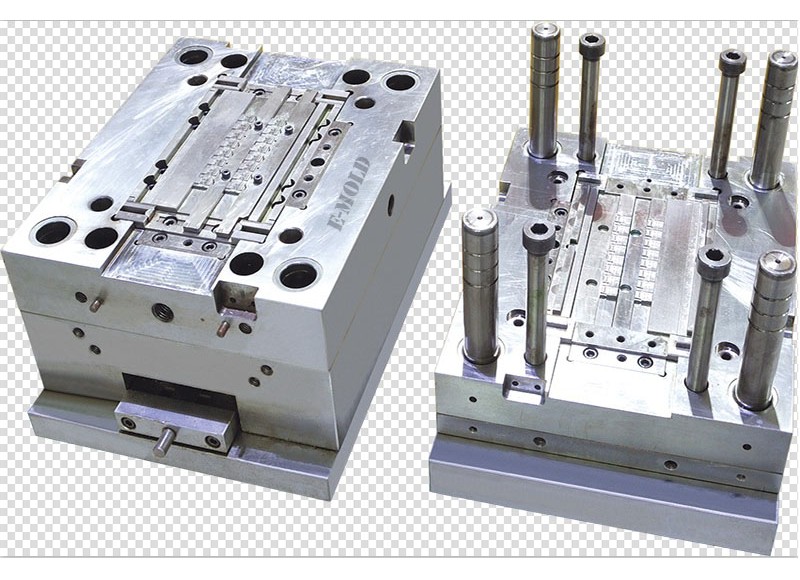

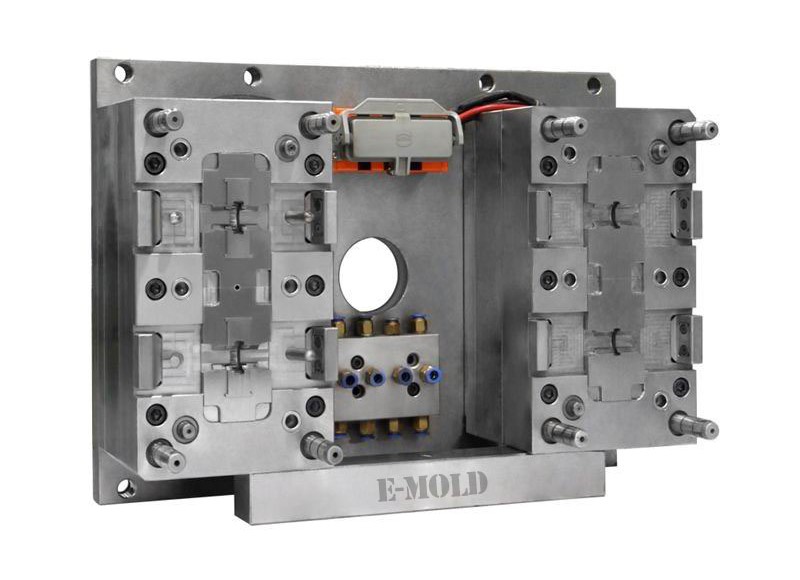

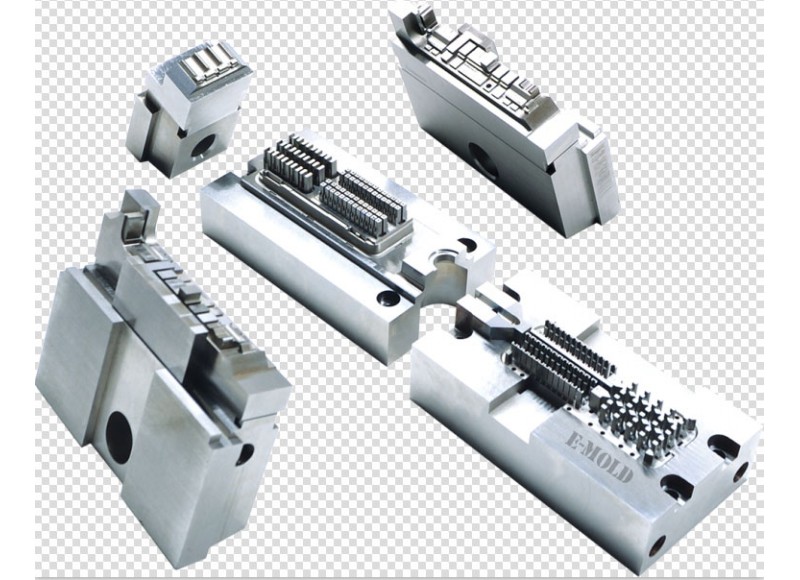

E-Mold has specialized in in Rapid prototyping, Low-volume manufacturing, Precision tooling, Mass Production, CNC Machining, and Sheet Metal parts.

With in-house mold design and manufacturing, our price is highly competitive.

Our experienced engineers fully support your business from technical and manufacturing perspectives.

With in-house mold design and manufacturing, our price is highly competitive.

Our experienced engineers fully support your business from technical and manufacturing perspectives.

We are :

Fast (You can have samples in number of days, not weeks),

Cost-effective (min 30% lower cost compare to our competitors),

Reliable Quality (ISO 9001 Certificated with multiple advanced inspection equipment).